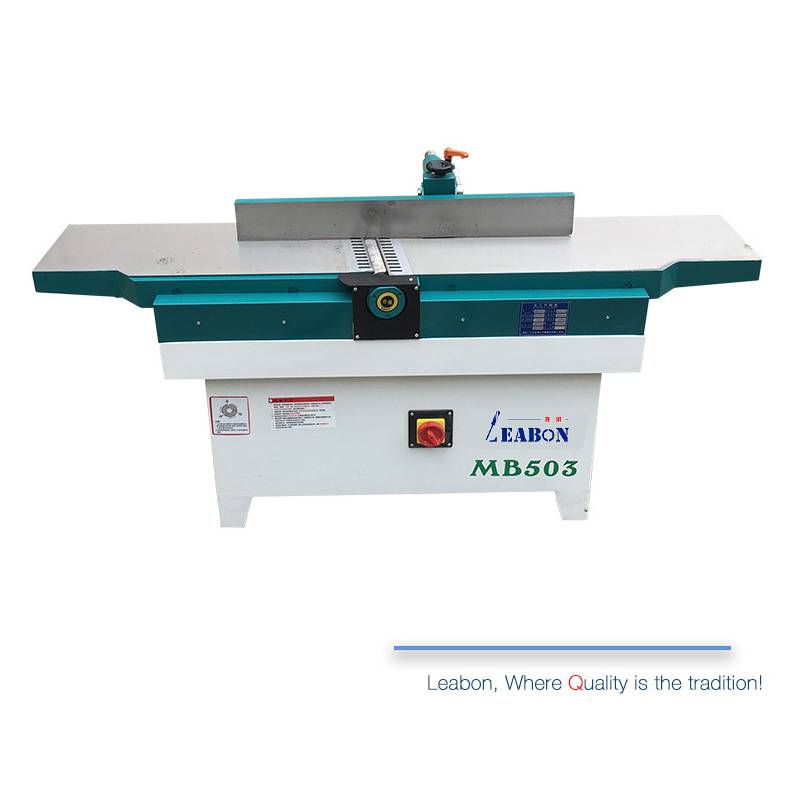

Quality Excellence

Our products are performed to the highest levels of quality, due to own five professional factories strong R&D, production and QC capability with rich manufacturing experience on each field.

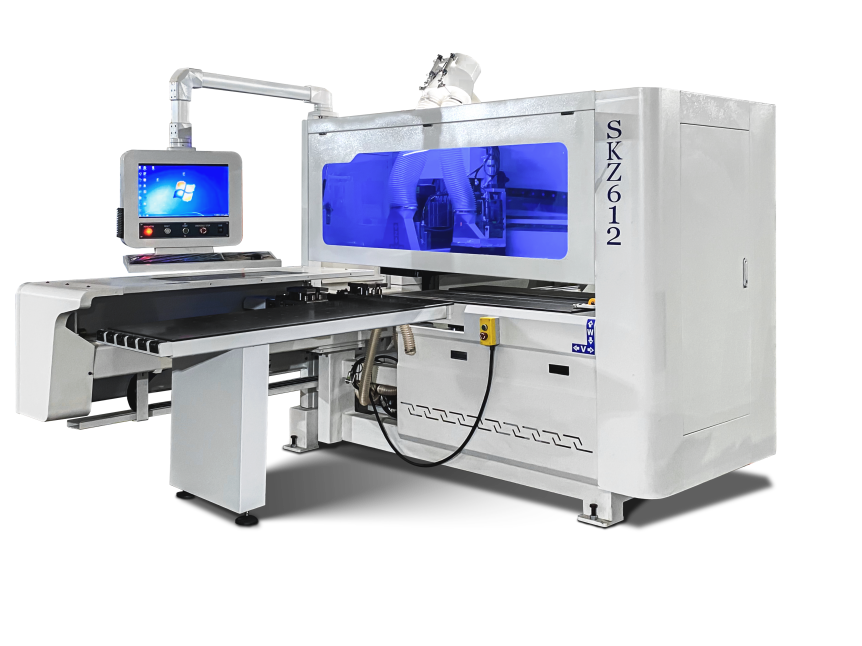

One Stop Shop

Supported by wide contacts and industry knowledge, located at China woodworking machinery manufacturing center, we are capable to offer a true one-stop-shop sourcing service to less your headache on manufacture selection.

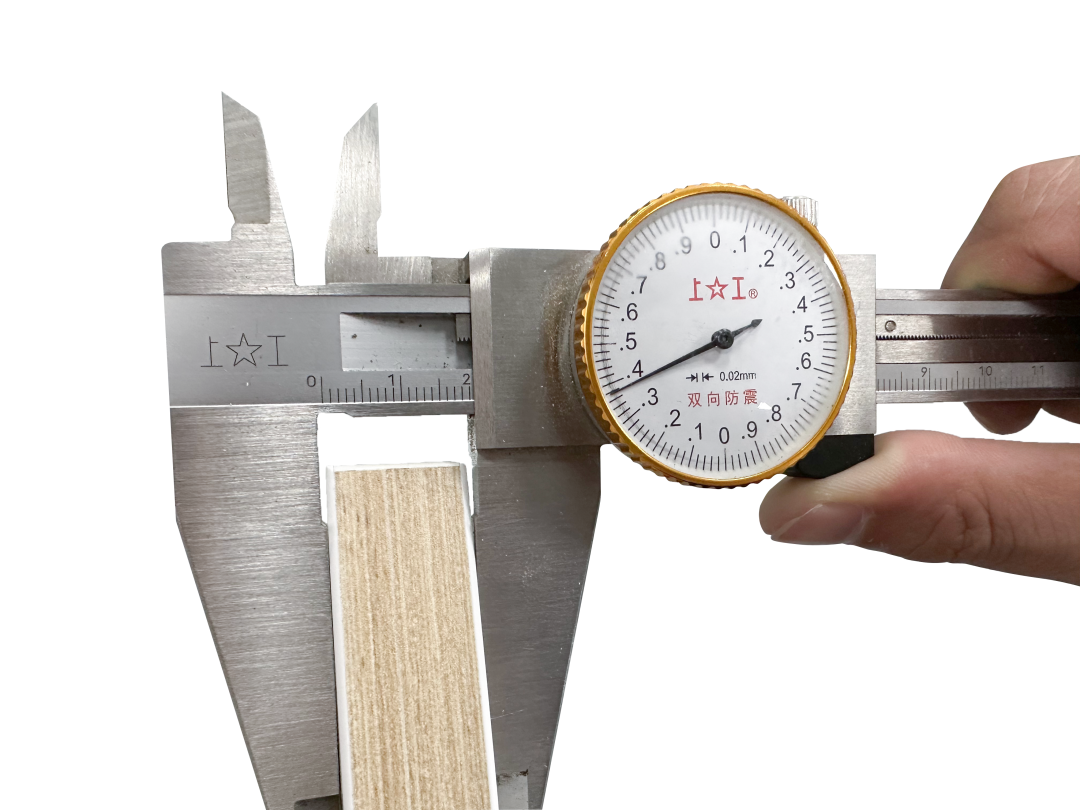

Real-time Response

Our export dept. staff are highly educated and trained. We guarantee all your demands will be treated as top priority, as a result all your inquires and after sales request will be treated and replied within max. 24 hours!