Cabinet door panels technology-

what is the difference between blister and coated film.

Generally, when you look at cabinet door panels in the market, you can see door panel materials with various styles and patterns. Usually, most of these different color patterns effects are achieved through the process of blister or coating. However, what is the difference between blister and coating for door panels?

Coated cabinet door panels and molded blister door panels are difficult to distinguish from the appearance. In principle, the film coating process is carried out on the substrate, which is different from the process flow used by the two. The emergence of the coating film technology has realized the imitation of solid wood to the greatest extent, and its fashionable and diverse shapes have become one of the few darlings in the market. The style is mainly European-style pastoral, which is more suitable for people who love nature and simplicity.

In addition, the coating process is more complicated than the blister process, which is an upgrade of the film coating process. The blister process has relatively few steps and the cost is much cheaper. If the product quality is not handled well, it is easy to produce air bubbles. The situation is easy to deform.

Although the film thickness of the coating process is thinner, because the process is covered on all six sides, it can better protect the substrate; second, it can effectively prevent the adhesive components in the substrate from escaping and use more For environmental protection; the third is that the six sides of the full-coated film can increase the load-bearing capacity of the board, which is not easy to deform and crack, and the other is slightly higher; the fourth is the connection method of the concave groove increases the possibility of mixing and matching door panels, which can provide richer styles Door panel selection.

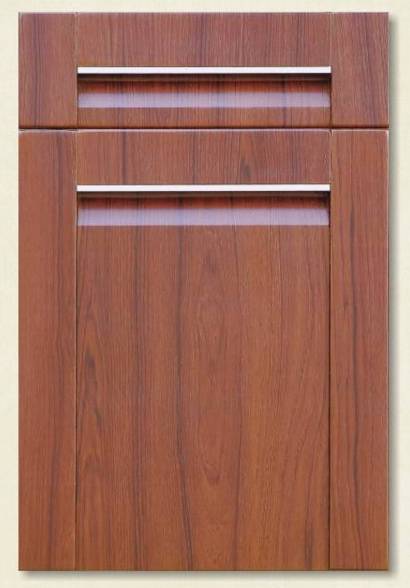

Coated Cabinet Door Panels

Considering the quality of these two process door panels from the difference between blister and cladding process of the door panel, the first thing is to see whether the overall color is uniform, whether the surface flatness has air bubbles and air infiltration, and the second is the door panel’s high temperature resistance, water resistance, moisture resistance, and scratch resistance. Whether the flower performance is good or not, the final pressure-bearing ability of the door panel base material is resistant to deformation. Generally speaking, the coating process has better control of the quality of the door panel than the blister product.

Advantages Of Coated Cabinet Door Panels

Strong texture. (Much depends on the quality of the film)

Strong profiling effect, can construct various lines and three-dimensional styles.

Dirt resistant and easy to clean.

No deformation, stable structure.

No seams and no edge sealing.

Disadvantages of coated cabinet door panels

The price of better quality coating film is more expensive, and the best quality is imported from Germany.

Choosing the cabinet door panel with coated film is equivalent to choosing the film, and the quality of the film becomes the main force that affects the quality of the cabinet. If you buy fake and inferior products, it will directly affect the service life of the cabinet.

Summarize

The appearance of coated cabinet door panels gives people who like solid wood cabinets but still want to stop, an extra choice. The natural and simple style suits the tastes of most people. It is worth noting that the quality of the coating film also determines the service life of the cabinet, so choosing a good quality coating film has become the top priority.