China the simplest and the most efficient composite door production line technology, with 300 doors daily output, do you want to know more about it?

Currently, the most popular wooden door is the composite door, which is durable, beautiful, affordable and popular among customers. Composite doors are a very good choice for manufacturers. Its production process is simple, production efficiency is high and investment cost is low.

.

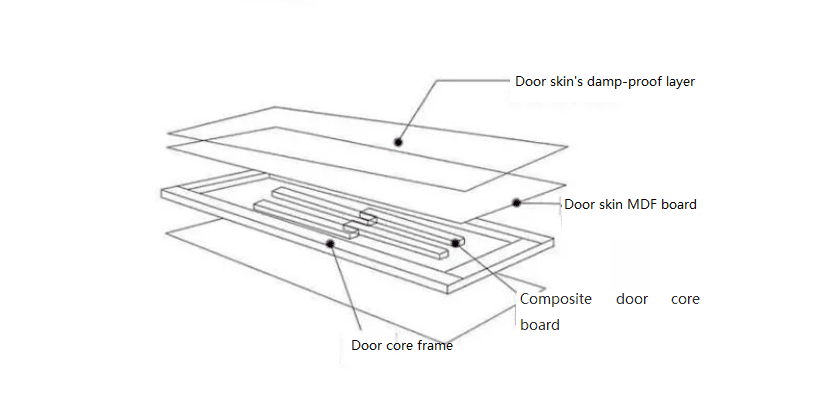

Composite door structure

Composite door is mainly composed of a door core board and two layers of door skin pressed together.

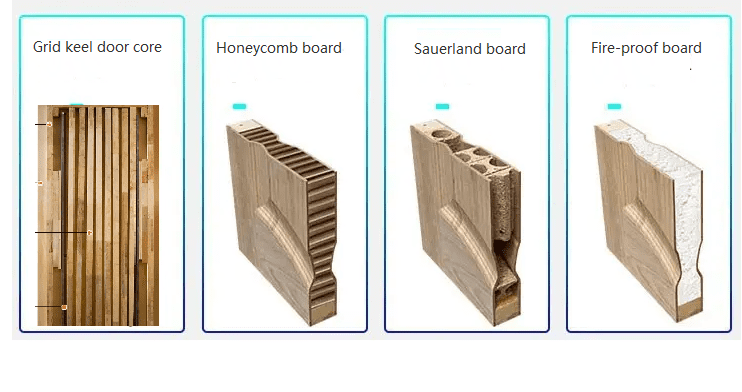

Door core board

Door core board can be divided into honeycomb board, grid keel door core, fire proof board and bridge hole mechanical board door core etc.

Honeycomb board door core price is cheap, but it is relatively poor in sound insulation and durability.

Grid keel door core is the strongest and most durable, and can be composed of particle board strips, multi-layer strips or solid wood strips. Bridge hole board door core has sound insulation effect, also called Sauerland board.

Door skin

Door skin is usually made of technological wood veneer or carbon crystal board. Its design is simple and beautiful, and the cost is low, about RMB 10-30 per sheet. Its main component is 3mm thick MDF board.It is moisture-proof and durable.

Composite door production line

Main steps of the composite door production line process: pressing, four-side cutting, edge banding, door lock hole hinge slot and closing slot.

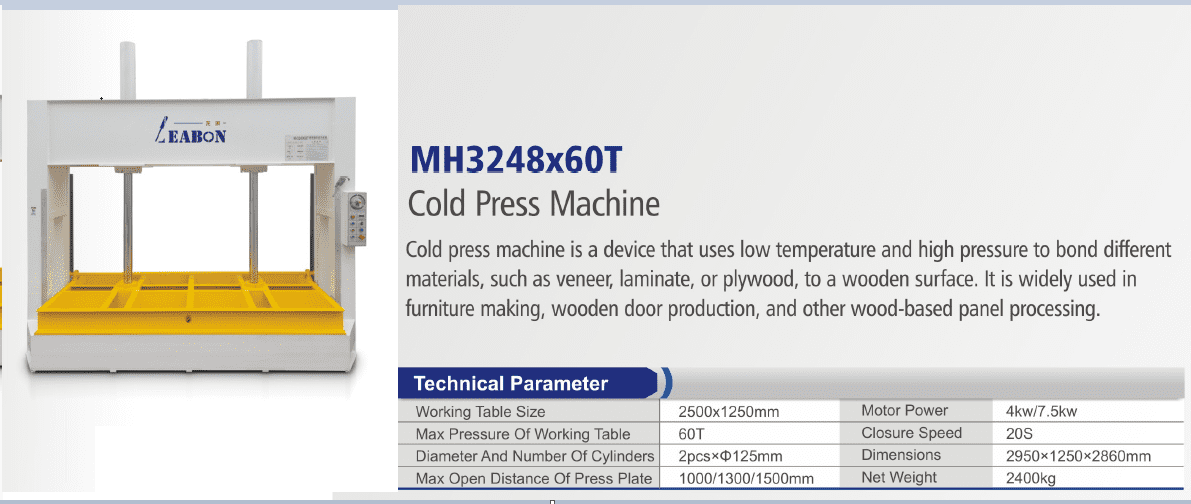

1.Gluing and pressing

Two glue spread machines can quickly complete simple gluing. For the pressing part, we can choose cold press and fast short-cycle AB glue door pressing production line. Cold press machine is low cost, but the pressing time is long. If you use a cold press, you need to press the door for about 3-4 hours, and you only can process to the next four-side sawing after the other 6 hours. However, if you use a fast short-cycle AB glue door pressing production line, one door can be finished within 1.5 minutes, and you can immediately enter the next production process.

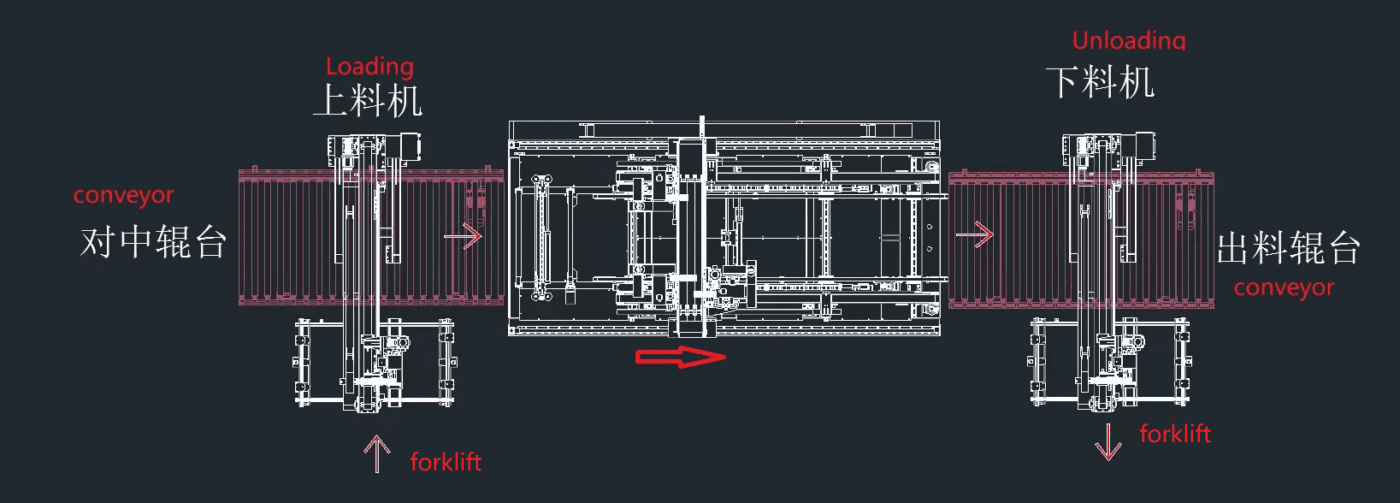

2.Four-side cutting

We recommend the automatic four-side sawing production line, which can complete finish cutting four sides at one time and automatically load and unload doors. Only 1-2 workers are needed to complete 300 doors per day.

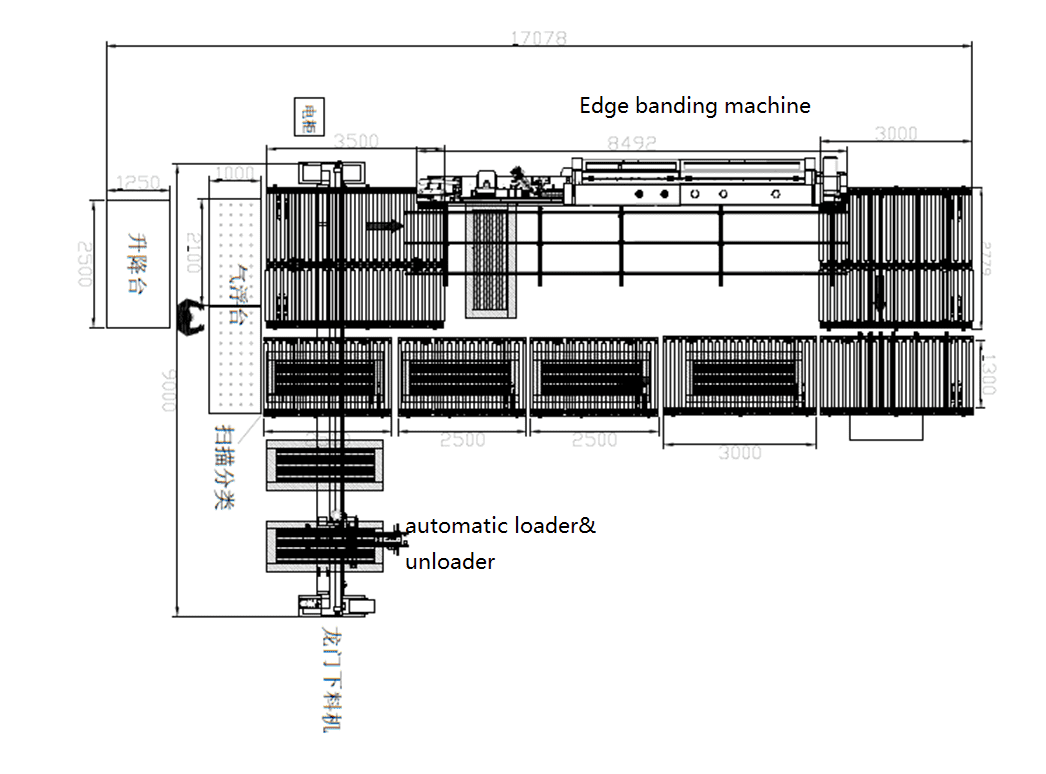

3.Four-side edge banding

One set of edge banding machine, one set of return conveyor line, one set of loading and unloading gantry machine, and one worker can easily complete the workload of 300 doors a day.

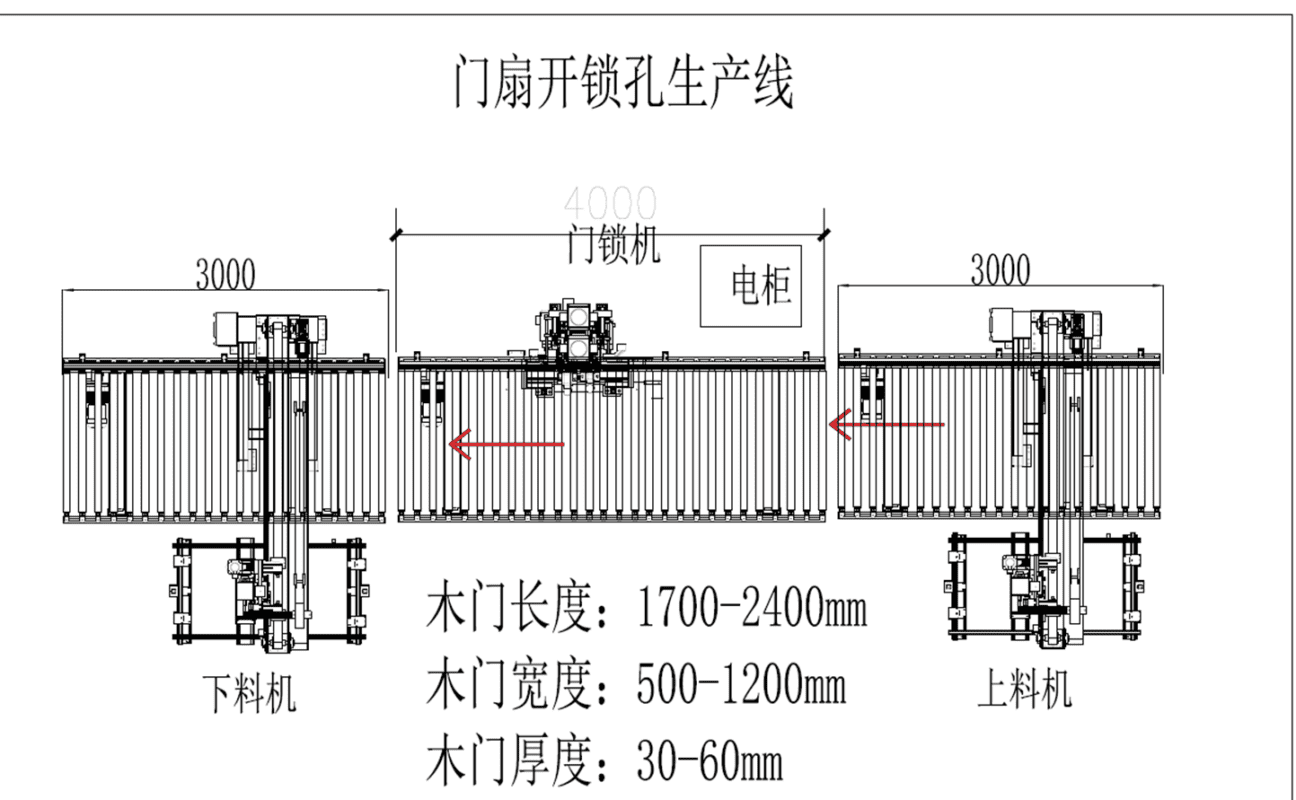

4.Door lock hole, hinge slot and closing slot process

We also recommend you an automatic production line for this processing, 2 unloading gantry machines, and 1 CNC door lock hole machine, which can complete the door lock hole, hinge slot and closing slot process at one time. If you do not need hinge slots and closing slots, we can customize the machine according to your requirements. This process requires 1-2 workers.

This production process is recommended, with low investment cost and few workers. 300 doors per day , it will bring you huge economic benefits, would you consider such a composite door production line?

If you have any questions about the composite door production line process, please contact us.

Fanny +86-13202927443