Traditional Sawing VS CNC Sawing

Let you know about China’s CNC Log Carrier Saw Machine

Under the background of the continuous growth of the global wood industry, the wood processing industry is facing serious challenges. Problems such as resource shortage, cost increase, and stricter safety and environmental protection requirements continue to emerge. The level of sawing efficiency and effectiveness plays a crucial role in the smooth progression of subsequent processes. Therefore, the transition from traditional sawing to CNC sawing is not only a reflection of technological progress, but also an inevitable trend of industry development.

01 Problems with traditional log sawing

Traditional log sawing mostly uses manual loading, which requires high physical fitness of workers and is prone to work-related accidents. At the same time, Operating a regular saw blade is difficult and requires professional skills, the traditional sawing process has a low degree of automation, low processing efficiency, large processing errors, and high technical requirements for workers, which further increases production costs and safety risks.

02 Efficient solution for log sawing

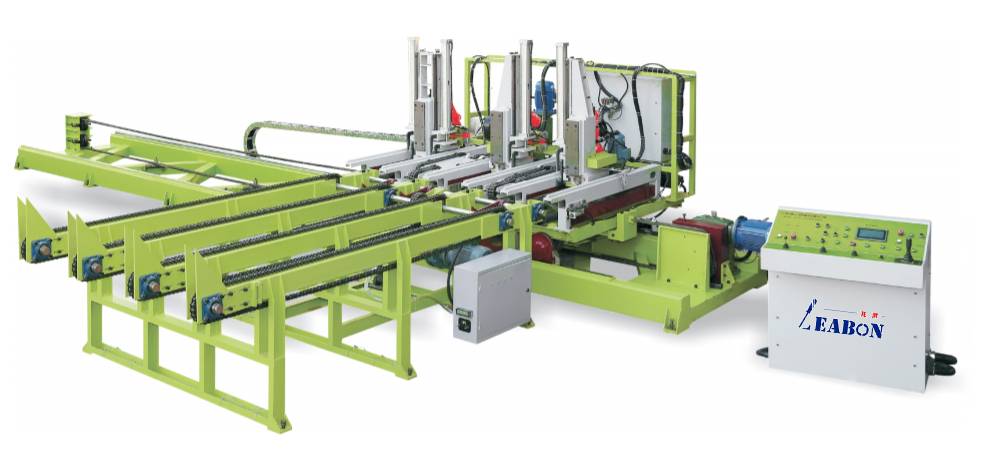

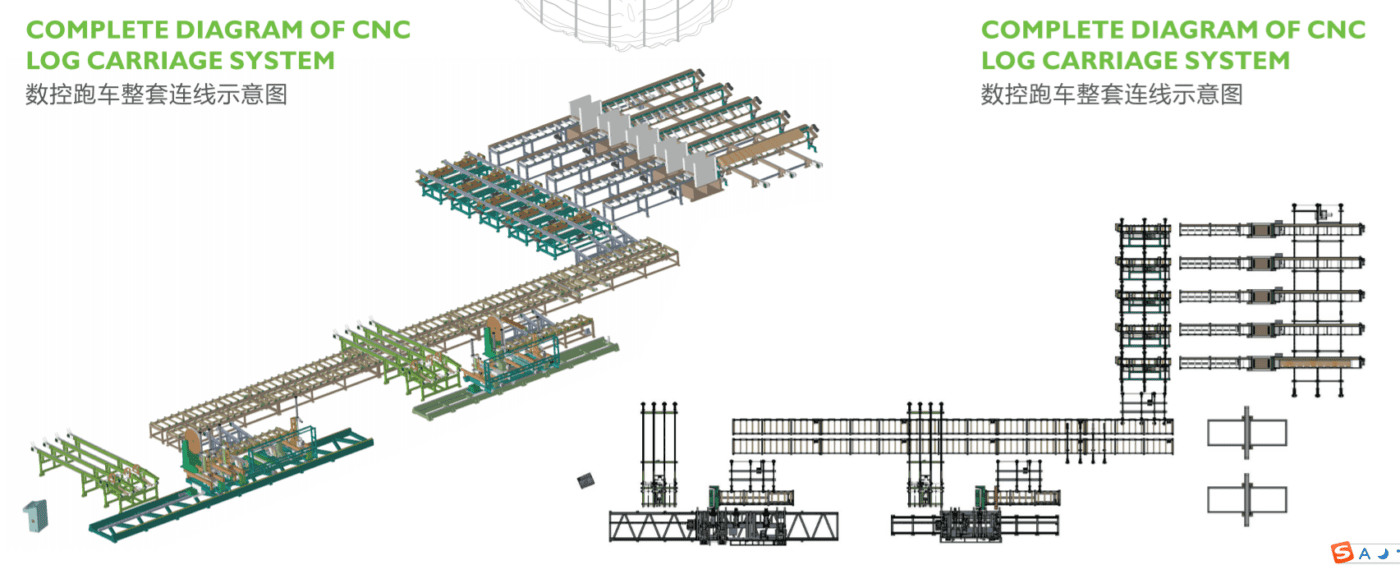

In order to deal with the problems of low feeding efficiency, complex saw blade operation, insufficient automation of sawing equipment, etc. encountered in traditional sawing technology in wood processing, many wood industry enterprises have actively introduced new high-performance equipment, such as CNC Log Carrier Saw Machine, Band Saw, Round Wood Frame Saw Machine,Square Wood Frame Saw etc., to achieve efficient production of log sawing. Among them, CNC sports car band saw has significant advantages as the core equipment of the solution.

03 Traditional sawing of logs VS CNC sawing

3-1 Comparison of equipment functions and features

Traditional sawing equipment usually uses manual loading, which is inefficient and prone to work-related accidents. Engineers have equipped CNC sawing equipment with an automatic loading rack. After the wood is forked to the loading rack by a forklift, the operator who controls the saw is responsible for operation, realizing simple and easy automatic loading. In addition, it uses an alloy saw blade, which makes the cutting path small and saves materials, so it can be operated by ordinary workers.

3-2 Comparison of processing effects and benefits

First, CNC sawing equipment can achieve higher processing accuracy and stability and reduce errors through precise CNC system control. Secondly, it has a high degree of automation, flexible operation and fast response, which can greatly improve processing efficiency. Thirdly, it simplifies the operation process, reduces the requirements for workers’ skills, and improves production safety. In addition, precise CNC processing and calculation of processing output rate can maximize material utilization. Finally, engineers equipped it with comprehensive safety protection devices to ensure the safety of the operation process and reduce safety risks.

04 Summary

In the context of the current multiple challenges faced by the wood industry, improving sawing efficiency and reducing production costs are the keys to industry development. By introducing new high-performance CNC equipment, many problems in traditional sawing processes can be effectively solved, production efficiency and product quality can be improved, and the market demand for high-quality and high-efficiency sawing products can be met. CNC sawing has significant advantages over traditional sawing in terms of functional characteristics and processing effects, and is an important direction for the future development of the wood industry.

If you have any questions about the CNC Log carrier saw machine, please contact us.

Vivian – [email protected]