1.What is soft-formed edge banding?

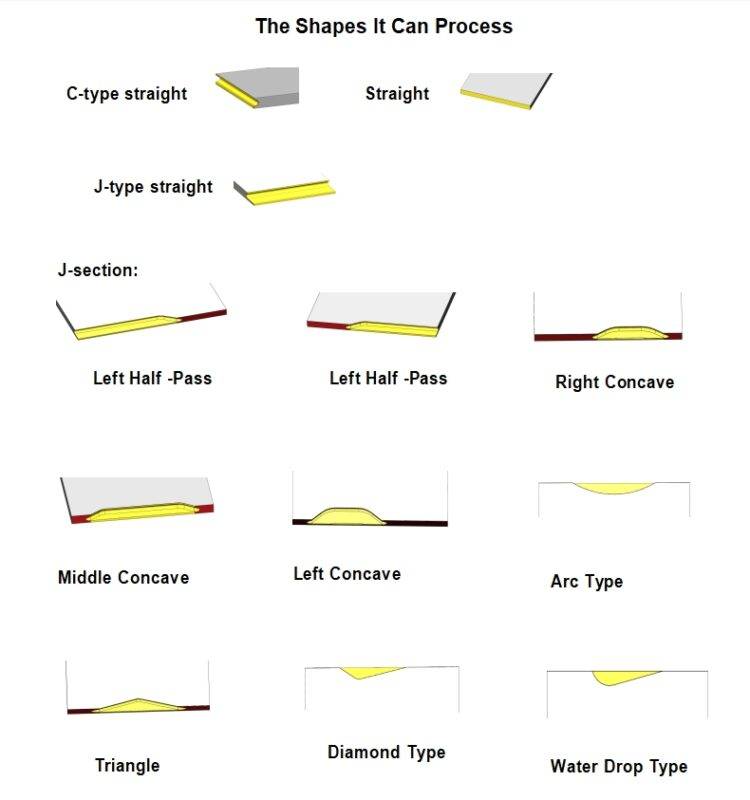

It is mainly used to process panels with formed or special-shaped edges. For example: J-shaped, L-shaped, 45-degree oblique straight edge, duckbill type and other conventional handle-free edge banding can all be achieved with soft-formed edge banding machines. The emergence of soft-formed edge banding machines meets the diverse needs of furniture formed edges.

2.Technical features of soft-formed edge banding equipment

2.1 Can provide a variety of “handle-free” processing

At present, the handle-free design is very popular in custom-made home furnishings, and there are many styles, but edge banding is not easy to do. Soft-formed edge banding machines can solve the problem of edge banding of special-shaped edges. It is equipped with a formed pre-milling unit, high-speed cutting of the formed surface, and it is convenient to change the tool. Usually one machine can meet a variety of edge banding needs, which can greatly reduce the cost investment and improve the quality and efficiency of processing.

Click me!

2.2 Easy to operate

After reading this, you may have such doubts: Generally speaking, the operation of machines that can realize diversified surface processing is relatively complicated. Don’t worry about this at all. Our soft forming edge banding equipment has a touch screen that can intuitively display the relevant equipment operation information. It is easy to operate. Click the operation page, switch the roller with one key, and the pressure beam automatically rises and falls, which is easy for novices to operate.

Details

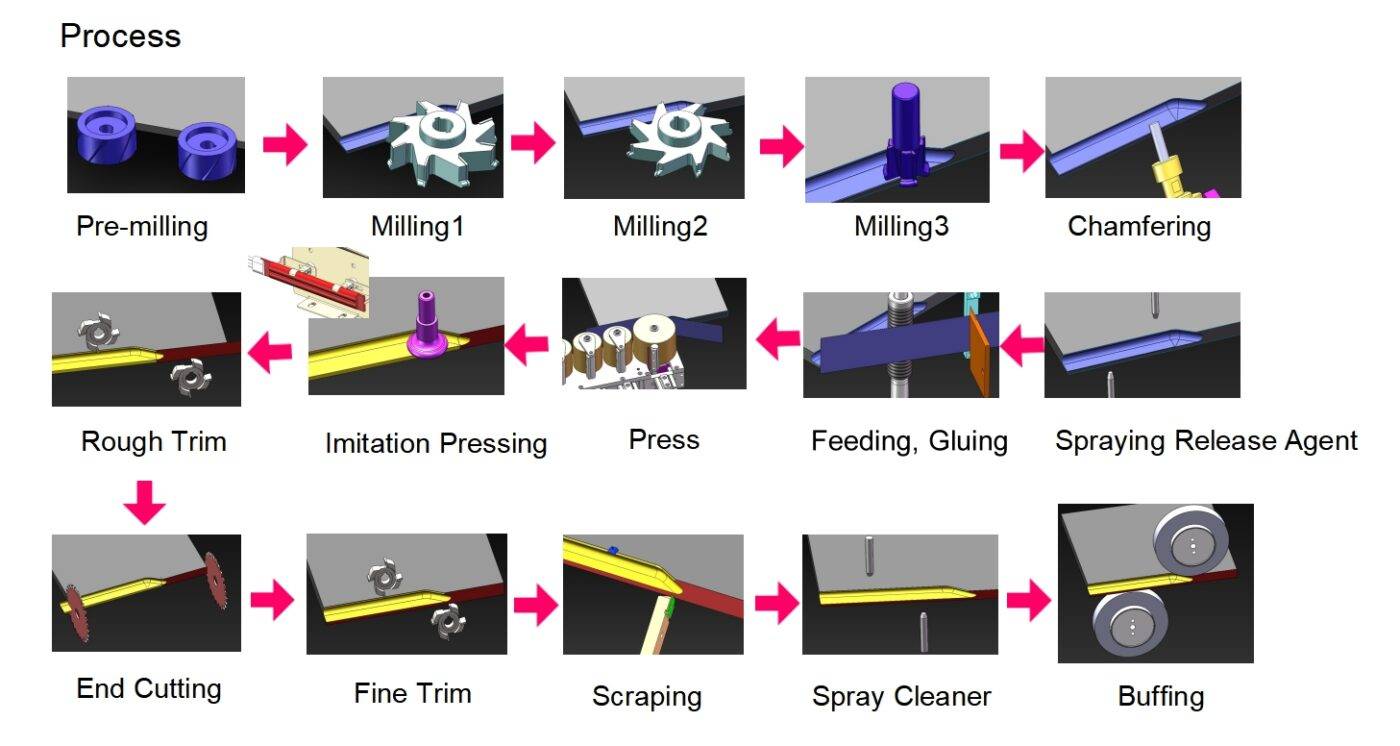

2.3 Good edge banding quality

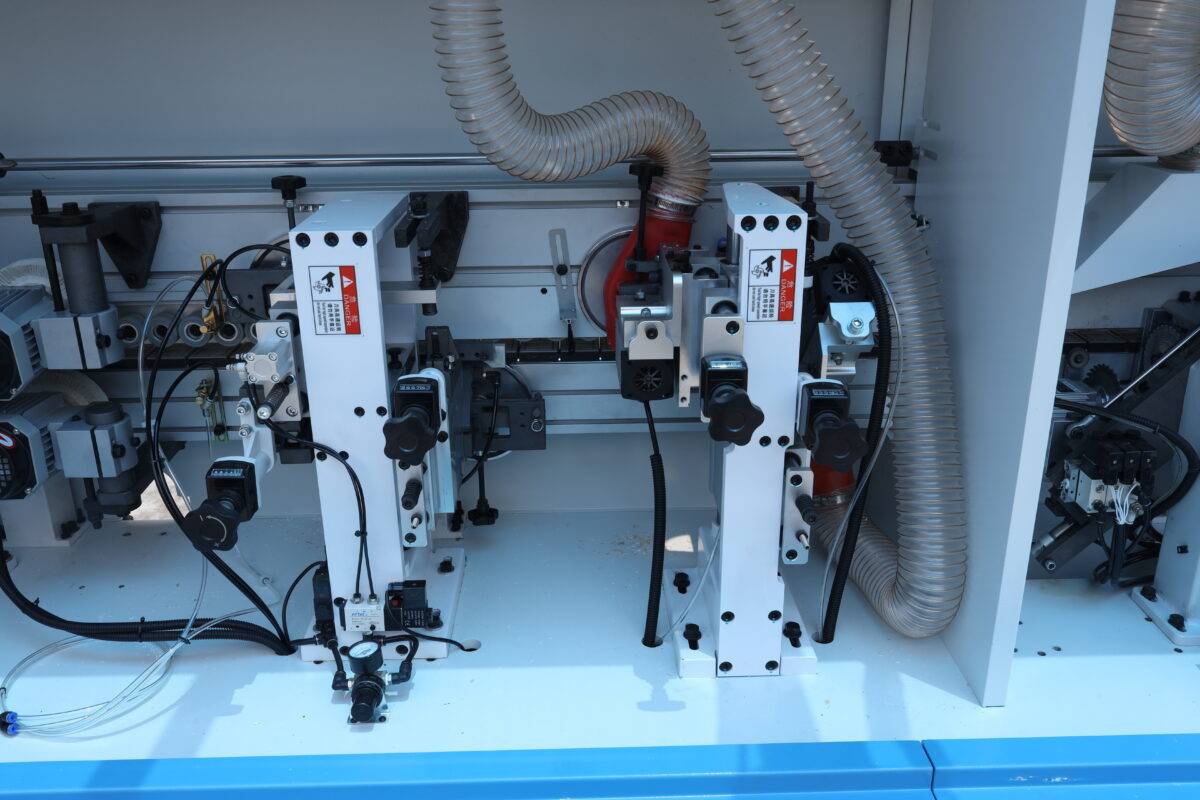

Simple operation can save a lot of complicated processing steps, thus ensuring the quality of edge banding. The machine adopts a multi-row combined pressing mechanism, which can make the edge banding more compact and more firmly adhered.

The machine is also quite stable in operation, because it is equipped with a sealing belt groove device for easy bending. On the one hand, it increases the power transmission edge banding, and on the other hand, it can make the machine more stable during the transmission process, ensuring that the edge adhesive is more firm, which largely guarantees the quality and efficiency of edge banding! Engineers also equipped it with a digital hot air blower, which can be heated twice to ensure better edge banding effect. At the same time, the high-end dual-motor tracking and profiling trimming can quickly and stably align the edge bands to ensure the smoothness and beauty of the workpiece end face.

And you don’t have to worry too much about the maintenance of the machine. For example, in the glue supply device, the machine uses a glue supply device with sol glue. The glue applied is not only uniform, but also fast, and it is more convenient to replace the glue supply device.

In the era of rapid technological updates, soft molding edge sealing technology promotes the development of customized home furnishings and creates high-end personalized home furnishings.

If you have any questions about the Soft Forming J/C Type Edge banding machine, please contact us.

Vivian – Leabon5@ileabon.com