Solid wood furniture not only has a long service life, but also preserves the texture of natural wood, looks beautiful and generous, and many consumers like it very much. In addition, solid wood furniture uses less glue during the production process, so it is very healthy and environmentally friendly. However, pure solid wood furniture has high requirements for materials and craftsmanship. Especially the processing of shapes and pattern details often requires meticulous craftsmanship. For modern solid wood furniture factories, it is costly and inefficient to use manual processing of complex shapes, so it is very important to have an excellent solid wood processing equipment. Our company’s Multi-Station Five-Axis Machining Center is your best choice.

Compared with traditional two-axis and three-axis CNC machine tools, five-axis CNC machining technology has more machining freedom, integrating computer control, high-performance servo drive and precision machining technology.

1.Basic Principles

The five-axis CNC machining center is a conventional X, Y, Z orthogonal three-axis drive system, with an additional tilt and rotation dual-axis rotation system. The X, Y, and Z coordinates determine the tool position, and the two rotation coordinates determine the tool direction, which can achieve five-axis linkage. This multi-axis linkage method enables the tool to process solid wood workpieces at different angles and directions, which can meet the processing needs of complex shapes and structures.

2.Technical Advantages

2-1 High processing precision:

Five-axis linkage can realize precise processing of solid wood workpieces, and can ensure the precision of processing dimensions and surface quality. For example, when processing the mortise and tenon structure of solid wood furniture, the tenon and mortise can be accurately processed to ensure the matching accuracy of the mortise and tenon.

2-2 High processing efficiency

Most of the cutting processing of the workpiece can be completed in one clamping, which reduces the number of clamping times and time and improves processing efficiency. At the same time, high-speed milling can condense the traditional multi-processing process into a high-speed cutting process, avoiding the cumulative precision error of the traditional multi-processing process.

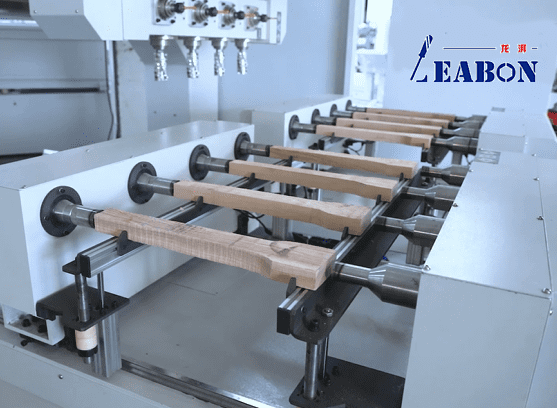

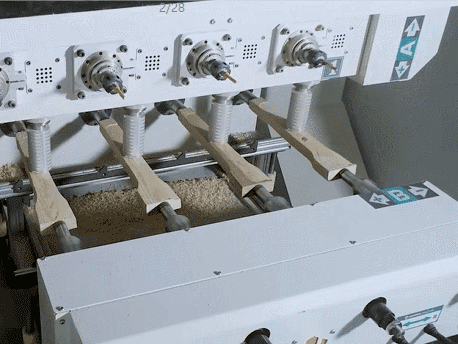

Double stations are carried out simultaneously, each station can clamp and process four pieces at a time, with high output.

2-3 Strong processing adaptability

It can process various complex shapes of solid wood workpieces, such as curved surfaces, special shapes, hollows, etc. It can easily process complex shapes and structures in solid wood furniture, such as curved backrests, carvings, etc.

Inconsistent workpiece surfaces and multiple changes in direction test technology, and turning, milling and rotating structures can easily cope with them.

Detailed display

3 Application Scope

The multi-station five-axis machining center JR1018 is suitable for processing solid wood and special-shaped parts, including solid wood coffee table legs, chair armrests, table and chair heels, sofa legs, etc. It can be formed by turning, milling and drilling in one go, and completed in batches. It can easily mill the waist and fine milling, and it is easy to pull the joint groove and open the mortise and tenon groove!

4 Summary

The processing of solid wood furniture is more complicated than that of panel furniture, and it has more requirements on the processing capacity of the equipment. A good equipment can make production more efficient, improve efficiency and save resources.

If you have any questions about the Multi-Station Five-Axis Machining Center, please contact us.

Vivian – [email protected]