With the development of panel furniture production, the appearance and quality of panels are more stringent. Panel edge banding is an indispensable part of panel furniture production. It has developed from traditional manual edge banding to mechanized and continuous production. It is also constantly improving. Depending on the form of the board and the side, edge banding machines mainly include straight-line, curved, soft-forming, laser, etc.

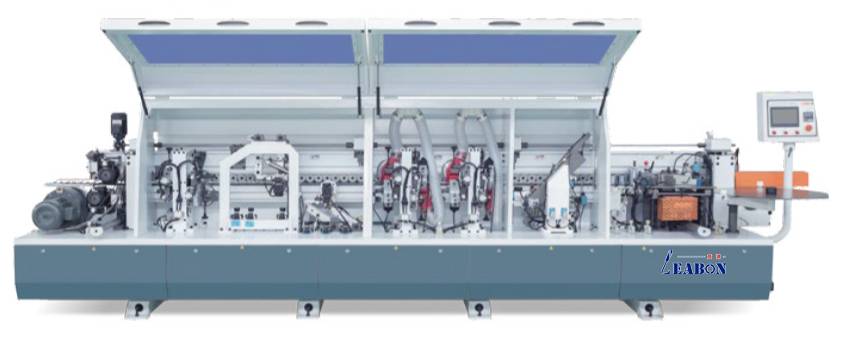

01 Straight Line Edge Banding Machine

The straight line edge banding machine is a widely used edge banding machine for straight-line panels at home and abroad. Its main functions can complete processes such as pre-milling, gluing, end cutting, rough trimming, fine trimming, four-heads corner rounding, scrapping, buffing.

02 Curved Line Edge Banding Machine

The curved line edge banding machine is suitable for edge banding of straight edges or irregular curved edges of panel components. It uses manual feeding, has a relatively simple structure, and has low production efficiency. However, it has strong applicability and can be used for edge banding of straight-line panel edges. The thickness of the sealing strip used in the curved and straight line edge banding machine is 0.4-1.5mm. Since manual feeding is required, the quality of its edge banding and trimming is greatly affected by human factors.

03 Soft forming edge banding machine

With the change of furniture shape and the use of curves, people have put forward requirements for special-shaped edge banding. Then the process and equipment of soft forming linear edge banding appeared. The functions of soft forming linear edge banding machine include milling, gluing, edge banding, soft forming glue pressing, end trimming, sanding, polishing and other processes. For light soft forming edge banding machine, the edge of the parts is first milled on various finishing milling machines. And the processes such as glue spraying and edge banding glue pressing are completed on the edge banding machine. For medium and large soft forming edge banding machines, the base material milling, sanding, glue spraying, edge banding glue pressing and other processes can be completed directly on the forming edge banding machine.

To learn more, you can read this article.

Click me!

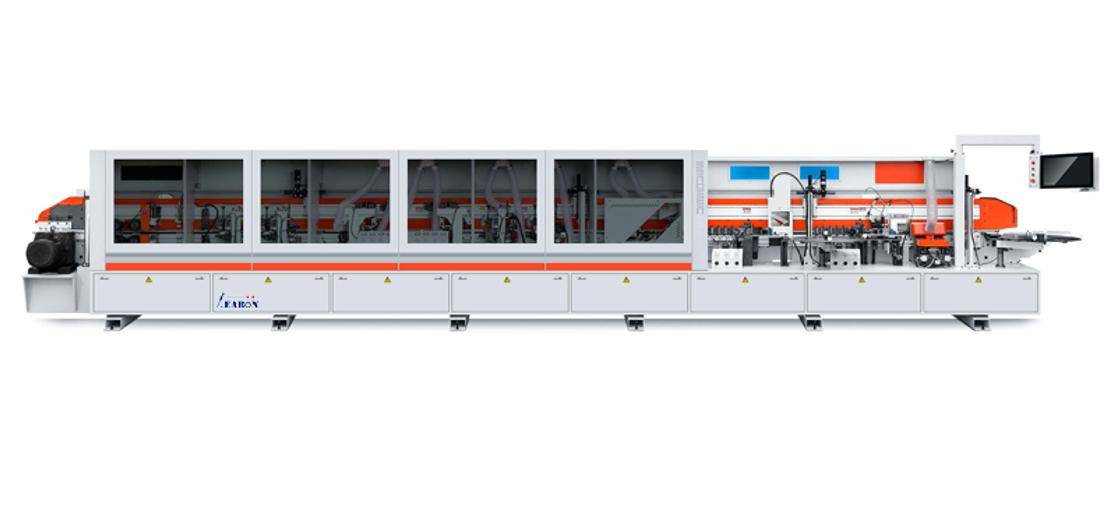

04 Laser edge banding machine

The traditional edge banding technology uses glue sealing technology, and its glue line is obvious and affects the appearance. And the glue material is easy to fall off, causing the board to be damp and deformed, and the service life is short. Laser edge banding can completely overcome the defects brought by traditional hot melt adhesive edge banding. Not only the board appearance is beautiful, but the entire process is also very environmentally friendly. The biggest feature of laser edge banding is that it does not require any additional gluing system.

05 Summary

Various types of edge banding equipment are suitable for different board edge banding requirements, and laser edge banding, as a new edge banding technology, can improve board quality and processing efficiency. The seamless edge banding advantage of laser edge banding has gradually become a benchmark trend in the panel furniture industry.

If you have any questions about the edge banding machine, please contact us.

Vivian – Leabon5@ileabon.com,MB/whatsapp:+86 18929978005