Avoid costly downtime with our expert woodworking machinery maintenance guide. Learn about dust control, lubrication, calibration, and safety checks to keep your industrial equipment running smoothly.

Author Archives: gddaniel

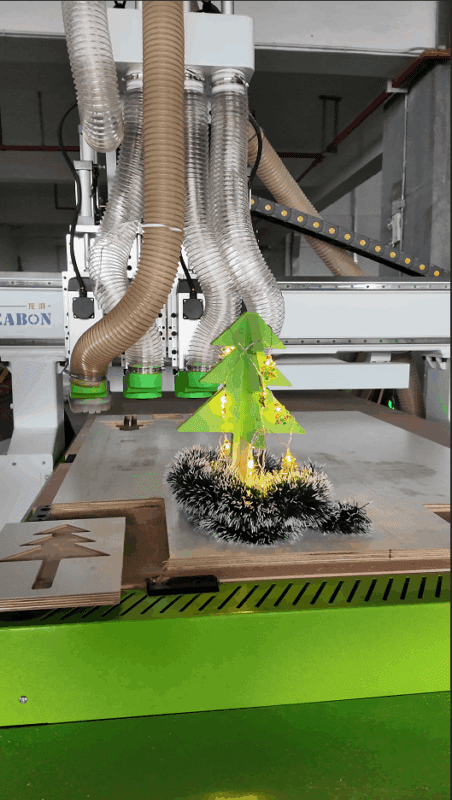

Our CNC nesting technology is perfect for custom furniture. It expertly cuts and carves complex shapes. With a 12-tool automatic changer, it seamlessly switches between tasks. Create intricate designs like this beautiful Christmas tree all in one step. Unlock new creativity and efficiency.

How CNC Routers Are Revolutionizing Furniture Making

In an increasingly competitive market, integrating automated and intelligent machinery is essential for businesses to reduce costs, enhance efficiency, and maintain a competitive edge. A high-performance Log Saw Machine is more than just a simple cutting tool; it is a strategic investment in modernizing, standardizing, and scaling your wood processing operations.

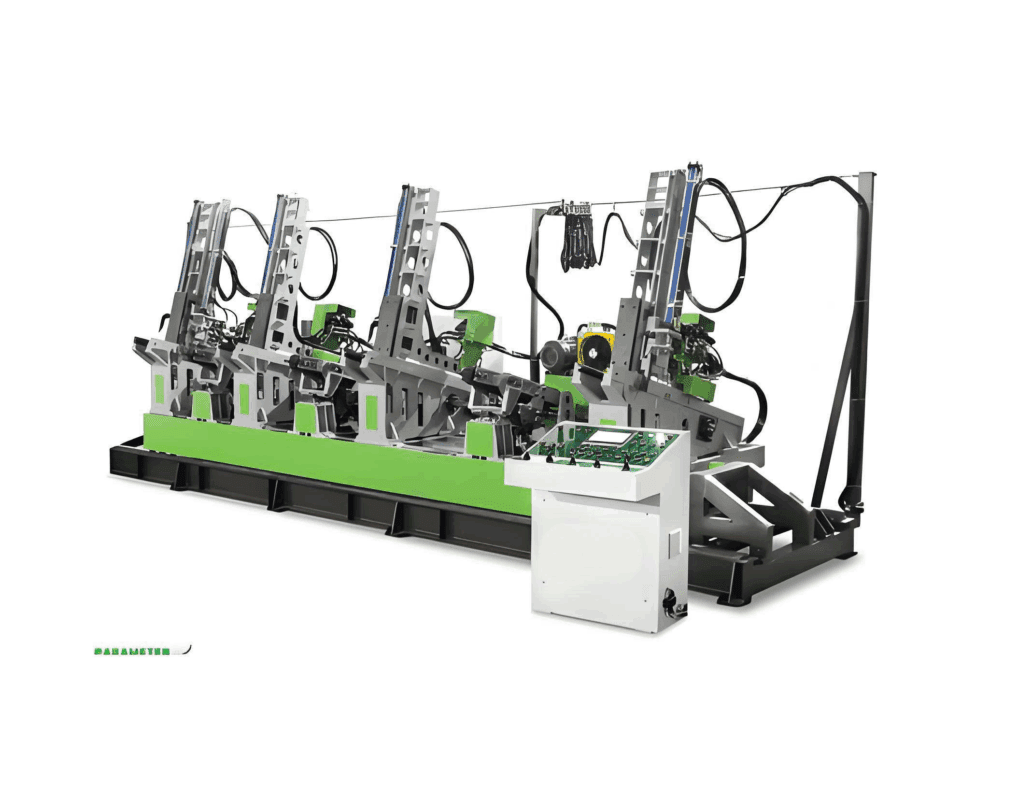

A woodworking drill a machine tool specifically designed for quickly and accurately drilling multiple holes in panel materials. Its core feature is its drill block layout: typically featuring horizontal, vertical, and tiltable drill blocks. It efficiently and precisely completes the various holes required for connecting panel furniture (such as wardrobes, cabinets, and bookcases), particularly 32mm system holes.

An engraving machine is a computer-controlled CNC machine that uses a high-speed rotating engraving tool head to perform fine processing on materials. You can think of it as an “automatic, versatile engraving pen.”

Celebrating Our Driving Force: Leabon Team

A pneumatic saw is a pneumatic cutting machine used for precise cutting of wood, plastic, metal, and other materials. Known for its safety, efficiency, and precision, it is widely used in furniture manufacturing, construction sites, metalworking, and various industries.

Edge banding machine is a special equipment used in the manufacture of panel furniture. Its core function is to automatically and firmly stick edge banding tape (such as PVC, ABS, veneer, solid wood strips, etc.) to the cut edge of the board.

The woodworking double-end tenoning machine is a high-precision CNC woodworking equipment specially designed for simultaneous tenon processing at both ends of wood. It can automatically complete the tenon at both ends of the workpiece through milling cutters, saw blades and other tools after accurate positioning and clamping.