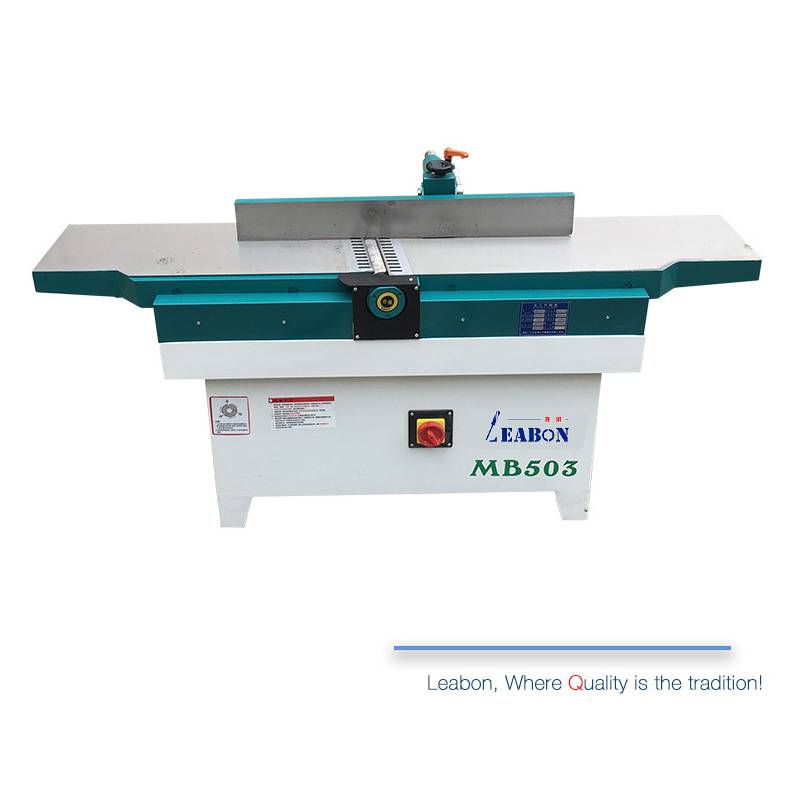

For any serious woodworking enthusiast or professional, a woodworking surface planer is an indispensable tool in the workshop. This powerful machine is designed to create perfectly smooth, flat, and uniform thickness across rough lumber.

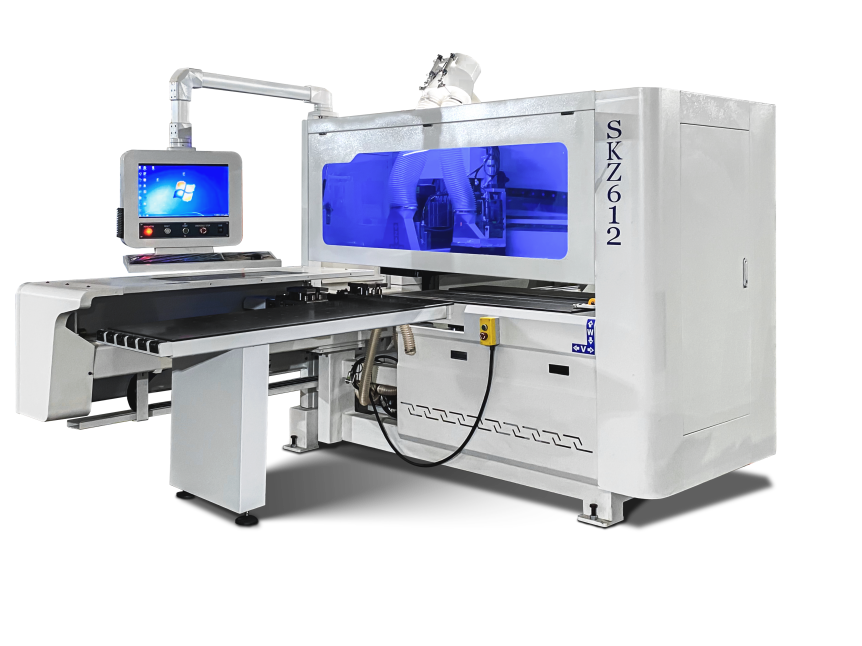

In the modern furniture production field, as consumers’ requirements for furniture quality and design continue to improve, traditional processing equipment can hardly meet enterprises’ dual needs for production efficiency and process precision. The six-sided drilling and milling machining center, with its powerful functions and flexible configurations, is becoming a key choice for many furniture manufacturers to enhance their competitiveness, featuring diversified processes, precise processing, intelligent operation and flexible configuration to provide an efficient, accurate and intelligent processing solution.

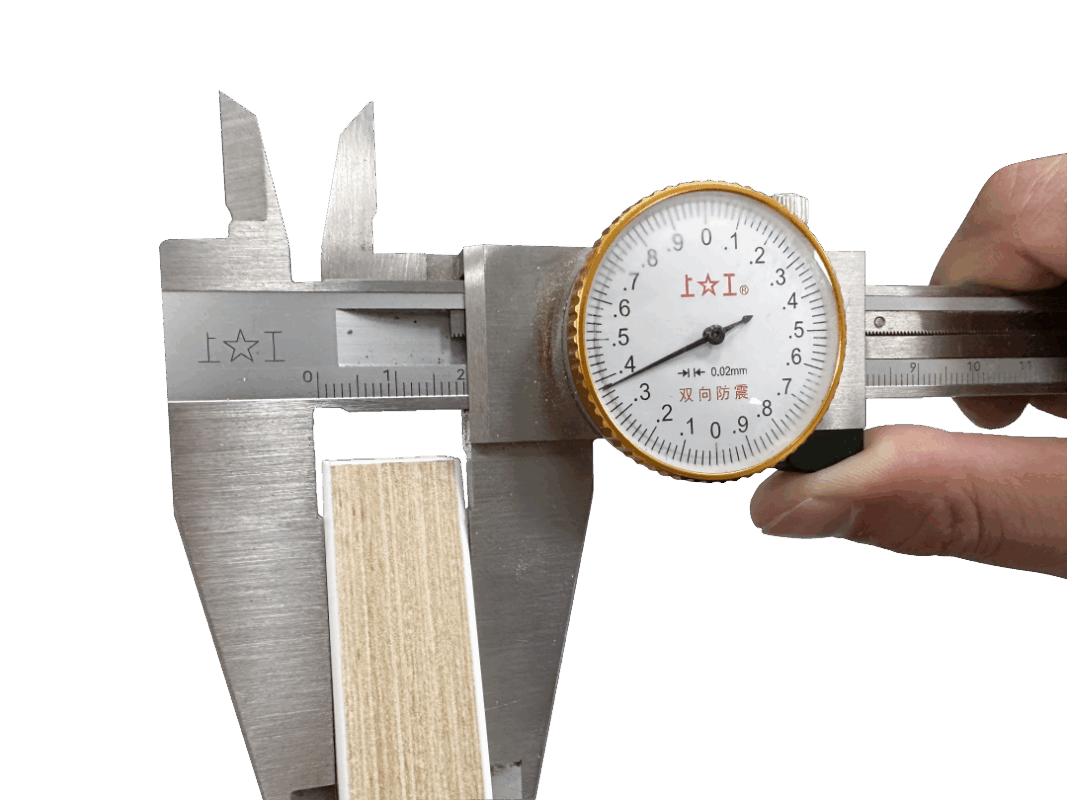

In the furniture production field, as traditional edge banding machines have poor adaptability to ultra-narrow boards (less than 2cm in width) and often cause various quality and efficiency problems, 1.8cm narrow board edge banding machine, with innovative anti-deviation feeding design, special pressing system, precision trimming scheme, high-precision core components and intelligent error-proof mechanisms, provides an ideal solution for furniture manufacturers to improve production efficiency and product quality.

In the realm of professional woodworking and cabinet manufacturing, speed and pinpoint accuracy are paramount. The multi boring machine, often simply called a line boring machine, stands as a cornerstone technology for achieving both. This specialized drill press has revolutionized the process of creating rows of consistent, perfectly aligned holes, forming the invisible backbone of assembled furniture.

Imagine you have a piece of rough, raw wood. You want to turn it into a smooth table, a sturdy chair, or a beautiful cabinet.

A precision tool for drilling accurate horizontal holes in woodworking projects.

In the world of custom furniture, cabinetry, and small-scale woodworking, achieving a professional, finished look often hinges on one critical detail: the clean, durable edge of a panel. While large industrial edge banders dominate factory floors, their size, cost, and complexity place them out of reach for many. Enter the compact or mini edge banding machine—a powerful, space-saving tool that is democratizing professional-quality finishes for workshops of all sizes.

The vacuum-adsorption horizontal band saw machine, with its high precision, high efficiency, and intelligent features, provides furniture manufacturers with a brand new solution.

Avoid costly downtime with our expert woodworking machinery maintenance guide. Learn about dust control, lubrication, calibration, and safety checks to keep your industrial equipment running smoothly.

A laser edge banding machine uses laser to instantly fuse special edge banding, achieving the highest quality edge banding effect of seamless, durable, and beautiful. It is a landmark technology in high-end panel furniture manufacturing.