Features of Automatic PUR Hot Melt Adhesive Woodworking Laminating Machine Line

- The laminating machine line is suitable for various materials such as Matt PVC, high-glossy PVC foil, Melamine paper, acrylic, PETG, aluminum foil, HPL, CPL on different boards such as MDF, plywood, partial board foam board, and PVC sheets.

- This machine has the advantages of no crushing, no bubbly, and good quality features.

- It is also advanced technical, high precision, and has reasonable composition, new structure, and easy operation. It can make complex-shaped workpieces, such as round, square, and curved shaped products. It is easy to set up and has stable performance, which reduces production costs and improves production efficiency.

- The machine is a fully automatic operation, which reduces labor intensity and improves production efficiency.

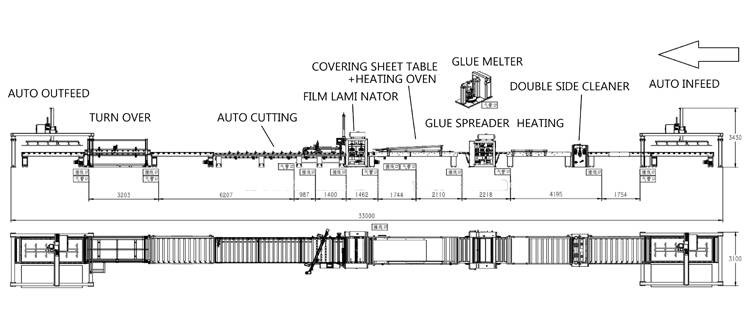

Schematic of PUR Hot Melt Laminating Machine Line

FUNCTIONS INTRODUCTION

55 gallon melting gule machine

Electromechanical equipment integrating temperature heating control, pressurization function, liquid conveying and extrusion coating functions

Automatic feeding and unloading machine

The vacuuming of the suction cup feeding is controlled by a customized vacuum generating device, which has good adsorption force and is safe and reliable.

Automatic flipping machine

Plate length: 2400~3050

Plate width: 1220

Plate thickness: 10~60mm

Power: 2.25KW

Flip speed: 4~5 times/min

Gluing machine

PLC centralized control. In addition to the bottom roll, each roll is controlled by a separate motor reducer frequency converter, controlled accurately by PLC, and the gluing is even and easy to operate.

Laminating machine

Adopt electric lift, touch screen control, simple and precise operation, pneumatic pressure. The transmission roller is controlled by a separate motor, and the transmission is stable without vibration and setback. The paper feeding shaft is an inflatable shaft, magnetic brake, automatic tension adjustment, and smooth lamination process.

Middle conveyor (with heating)

The conveying rollers are arranged in an oblique row, and the plate always leans against the block during the conveying process until the exit plate is in a straight line, which effectively prevents the plate from shifting during the conveying process. The heating adopts infrared lamp, the heating speed is fast, and it is equipped with an incoming sensor switch, which can effectively save electricity.

OUR CERTIFICATES