Product Features

1.Lamination Vacuum Press Machine is a double-station automatic operation mode. The left and right stations can run continuously without waiting. The current issue is that each workflow can be completed in as little as 60 seconds, effectively maximizing work efficiency.

2.The control system features a PLC touch screen, making the man-machine interface user-friendly. Users can easily adjust parameters based on the specific materials of PVC film. A parameter table is provided for reference before the system leaves the factory. After making the necessary adjustments, simply press the start button to begin the process.

3.PVC membrane vacuum press machine with a high-speed vacuum pump with a rated speed of 100m³/h (optional) and a super-large vacuum tank. It can quickly reach the set pressure value in a short time, with fast pumping speed and strong force. Shorten the suction molding time and improve work efficiency.

Details Images

High speed direct connection motor

The worktable runs with high-speed direct-connected motor drive and fequency control. Therefore,the method of decelerating and stopping at high speed effectively prevents the plate displaced. In addition,it also shortens the running time and improves work efficiency.

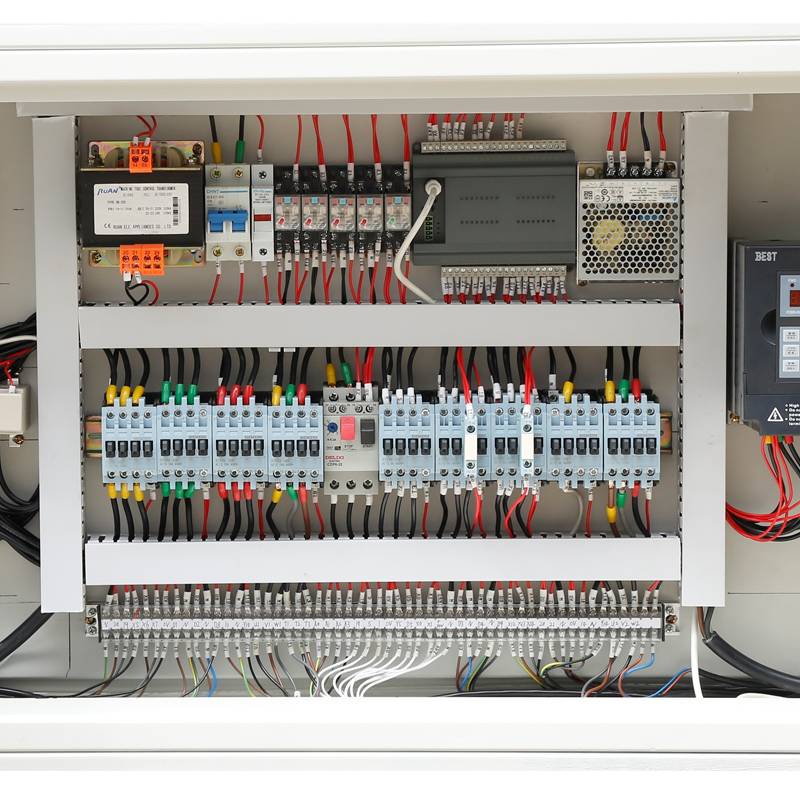

Electric

Electric Parts of Vacuum Membrane Press Machine.

High speed vacuum pump

The machine is equipped with a high-speed vacuum pump, boasting a rated speed of 100m³/h (optional), along with an oversized vacuum tank. As a result, the required pressure can be achieved in a short time, and the pumping speed is notably fast. Consequently, this shortens the molding time and significantly improves working efficiency. This combination of features makes the machine highly effective for various applications.

Floating up heating way

It equips with the function of floating and heating of PVC film, which can solve the phenomenon of wrinkles or shaded area on the middle and low grade soft PVC film, and improve the uniformity of heat on the surface of PVC film.

OUR CERTIFICATES