China Automatic Straight Line Edge Banding Machine T-600 Main Features

2. PLC use Tiawan Delta brand, air cylinder use SCM from Japan, INNA liner track, Honeywell limitation switch, all key parts we choose market tested best brands to try to guarantee our edge bander performance and let our customers can enjoy to use our machines.

3. Independent electric lifting up and down system, simple and convenient.

4. Precise encoder control, high speed.

5. Special polishing structure, motor angle can be universal adjusted, make the PVC/Acrylic/ABS/Veneer band polishing and buffing to the best.

6. Glue spray clean system is optional, it’s good to remove the glue and dirty on MDF/Wood panel during plastic banding process.

7. With such powerful functions and high efficiency, our straight line banding machine price is very competitive. As professional China banding equipment manufacture and supplier, We give factory price direct to final customer, you buy, you save!

8. PUR edge banding function is optional to give you more durable, no gap banding experience!

9. Veneer/wood banding is optional to be installed!

Automatic Edge Banding Machine T-600

Our shared future

Our Edge Banding Machine Factory Workshop

Quality and Heavy Duty Body

Automatic Tape Changing System is Optional

functions introduction

Click edit button to change this text.

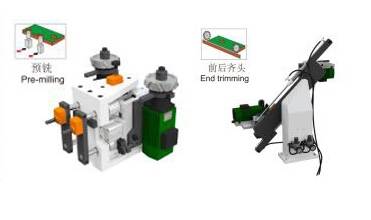

PRE-MILLING AND END TRIM

The buffing device adopts cotton material polishing wheel to sand the finished edge band more smoothly.

The gluing equipment adopts a special structure to distribute the glue evenly on the tape panel and the tape to ensure a stronger adhesion.

Buffing and Gluing

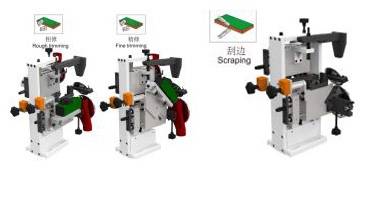

Fine and rough trim facilities are used to remove the extra material on band, it adopts mould automatically track and high frequency high speed motor, ensure the plain and smooth of work piece top and bottom parts.

Fine Trim / Rough Trim and ScrappingCE Certificate