Leabon Flexible Pass-Through Assembly Machine Main Features:

1.The high-frequency information technology is used for heating, the temperature is uniform, the adhesive develops rapidly under the pressure state of the precise control of the motor, the curing is improved, and the gluing quality is good, which greatly reduces the cracking of the wooden door buckle caused by the quality of the gluing

2.The flexible pass-through framing machine realizes nail-free gluing, eliminating the need for nailing, puttingty, drying and other processes, the surface of the workpiece is not damaged, and the appearance is good

In the field of all-wood customization, the processing procedures of wooden doors, cabinet doors and wall panels are all completed by splicing. The effect of splicing and assembly determines the quality and appearance of the product, and the application of high-frequency heating technology in this process has greatly improved The processing efficiency and processing effect are improved; at the same time, the call for the development of flexible furniture and equipment is getting louder and louder.

Multifunctional

Various types of wooden doors, wardrobe doors and cabinet doors can be assembled

Assembling efficiency

1.One door a minute

2.It can be connected to the customer’s MES/ERP system to realize scanning code processing, system upgrade, and remote control

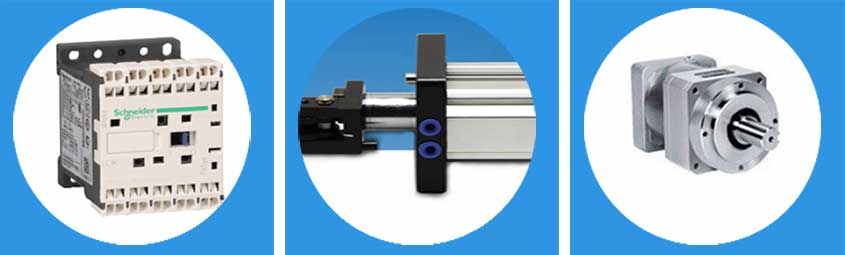

Configuration

1. French Schneider Electric parts: automatic tool change, high speed, strong cutting force, convenient and fast

OUR CETIFICATE