Woodworking CNC Curve Saw Machine for Curved Wood Processing(MJS 1620B) Features

1.Advanced CNC control features, powerful function and easy operation, and fully automatic cutting operation.

2.High efficiency curve cutting without need of copy template or mould.

3.The entire feeding mechanism is manufactured from aluminum alloy, featuring light weight, maximum durability and beautiful outlook.

4.Panel feed is driven by a servo motor and transmitted through rack, that permits fast feeding motions and high positioning accuracy.

5.Slide ways are mounted with high precision linear guide ways for stable and smooth feeding motions. • CNC curve saw blade swiveling angle: 90 ̊ and it’s programmable. • All travels are driven by servo motors combined with the use of Germany linear guide ways.

6.Aluminum alloy automatic feeding mechanism features light weight, maximum durability and elegance.

7.Rugged machine construction exhibits outstanding stability.

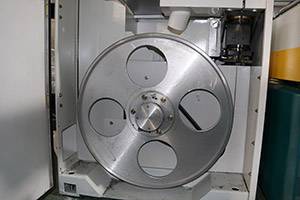

PRODUCT DETAIL

The processing efficiency is high, the processing work-piece surface is good quality and no need to be crossed.

Save the timber, processing range is wide, automatic programming, the operation is easy, man-machine division, it can reduce the risk of industrial injury, it is an ideal production equipment for wood furniture and other enterprises.

This machine no need to rotate the saw blade, it can easily rotate 90′ , and the used saw range is wide, scientific structure design avoids the loss brought by the saw breaking and loss, extend the life of the saw blade.

CNC band saw machine is an affordable and economy machine, it can solve the curve processing for hundreds of users.

The open feeding platform is more convenient, and the sawing efficiency is higher. Strong cylinder fixtures, the clamping device is reliable, clamping range is wide, it can saw the multi-layer sheet synchronously.

The saw clamping device can enhance its precision.

Our Certificates