Branded Electrical Parts

The electrical parts use Schneider Brand or SIEMENS Brand.

Side View

Main spindle of the equipment use Japan NSK and Sino-Japan manufactured TR bearing.

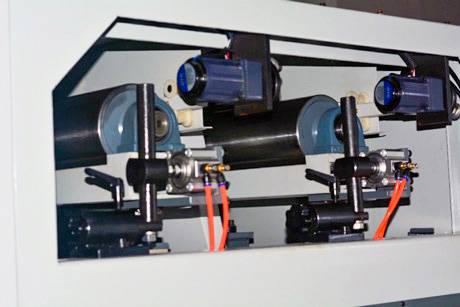

Heavy Duty 2 Rollers Structure

Sanding paper swing controlled by Omran photoelectric.

Drum Sander Conveyor

Conveyor use marble material, its shape won’t be changed because of temperature. Precision and grinding duration is higher than steel conveyor.

Woodworking Drum Sander machine SR-RP1000

- Work piece thickness displayed by micro-computer button type thickness dis-player, precise and durable.

- Sanding paper swing controlled by air power, swing is smooth and even.

- Front and back double emergency knob, can control the machine to urgently stop within 3-5 Seconds.

- Faults Display fitted (sanding paper right and left deviation, inadequate air pressure, emergency knob, and over thickness work piece). It’s easy to judge basic equipment trouble. Faults emergency stop adopts automatically descend protection facility, thus the panel surface won’t be damaged from emergency stop.

- Use branded conveyor, grinding duration is 3-5 times as ordinary conveyor.

- Conveyor fit with automatic centering facility.

- Conveyor speed adjusted by frequency controller, easy adjusting. It can be adjusted as per the work piece in processing to improve sanding quality.

- Sanding paper swing controlled by Omran photoelectric.

- 1st group sanding roller use 240mm diameter eccentric steel thickness roller, high smoothness, heavy sanding quantity; 2nd group roller use 210mm diameter, 70 shore hardness thickness roller and fit with ex-tractable polishing pad.

- Conveyor use T shape screw pole craft, high precision.

- Main motor automatically star triangle(Less pressure) start.

- Main spindle of the equipment use Japan NSK and Sino-Japan manufactured TR bearing.

- The electrical parts use Schneider Brand .

- Conveyor use marble material, its shape won’t be changed because of temperature. Precision and grinding duration is higher than steel conveyor.