With the continuous development of science and technology, the woodworking industry has also ushered in a wave of intelligence.

Woodworking Computer Panel Saw , have transformed traditional carpentry by merging digital technology with cutting tools. These automated systems enable unparalleled accuracy, speed, and customization, making them essential in modern woodworking workshops and factories.

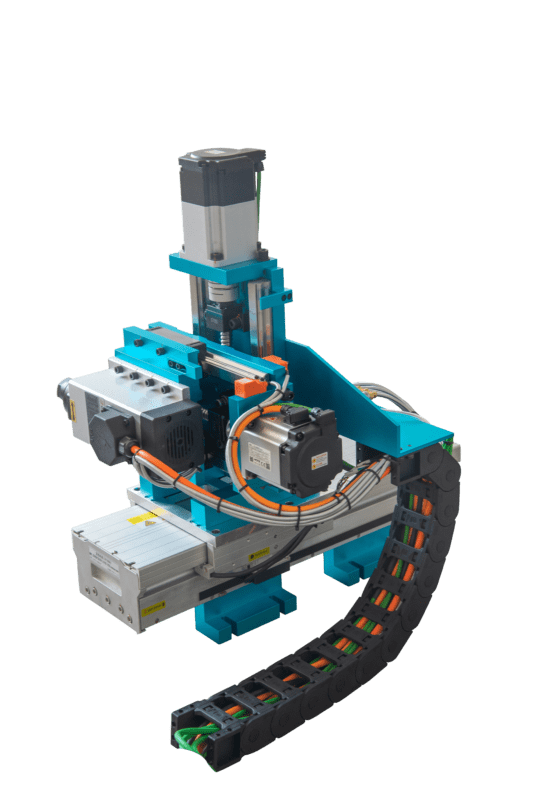

The magnetic suspension synchronous side hole machine, with innovative magnetic suspension technology as the core, is specially designed to create “high-precision, high-efficiency, high-flexibility” intelligent processing solutions for whole-house customization companies!

Discover the best furniture accessories and woodworking machinery at the 2025 Exhibition. Expand your market and find unlimited business opportunities. All the information is collected by us, including the specific number of exhibitors, number of visitors, number of sessions, etc., to help you choose a more suitable exhibition.

Choosing the right edge banding machine is crucial for high-quality panel furniture production. Learn how to select the perfect machine for your needs. Leabon has a variety of edge banding machines for you to choose from, supporting customization.

The CNC cutting machine is one of the important production equipment of current furniture manufacturers. The equipment has a high degree of automation and can help manufacturers save costs. That is, it reduces labor cost input, improves board utilization, and reduces equipment maintenance costs.